In the realm of door hardware, hinges play a critical role in the functionality and aesthetic appeal of doors and furniture.

Among the various types of hinges available, butterfly hinges stand out for their unique design and versatility. For wholesalers and importers, understanding the quality and durability of these hinges is paramount.

This blog delves into the essentials of butterfly hinges, their historical significance, installation techniques, and the factors that determine their quality and durability.

Type of hinges for doors

Before we dive into butterfly hinges, it’s essential to have a broad understanding of the various hinge types available in the market. Here are a few common types:

• Butt Hinges: These are the most common type of hinges used in doors. They consist of two identical leaves that are attached to the abutting surfaces of a door and its frame.

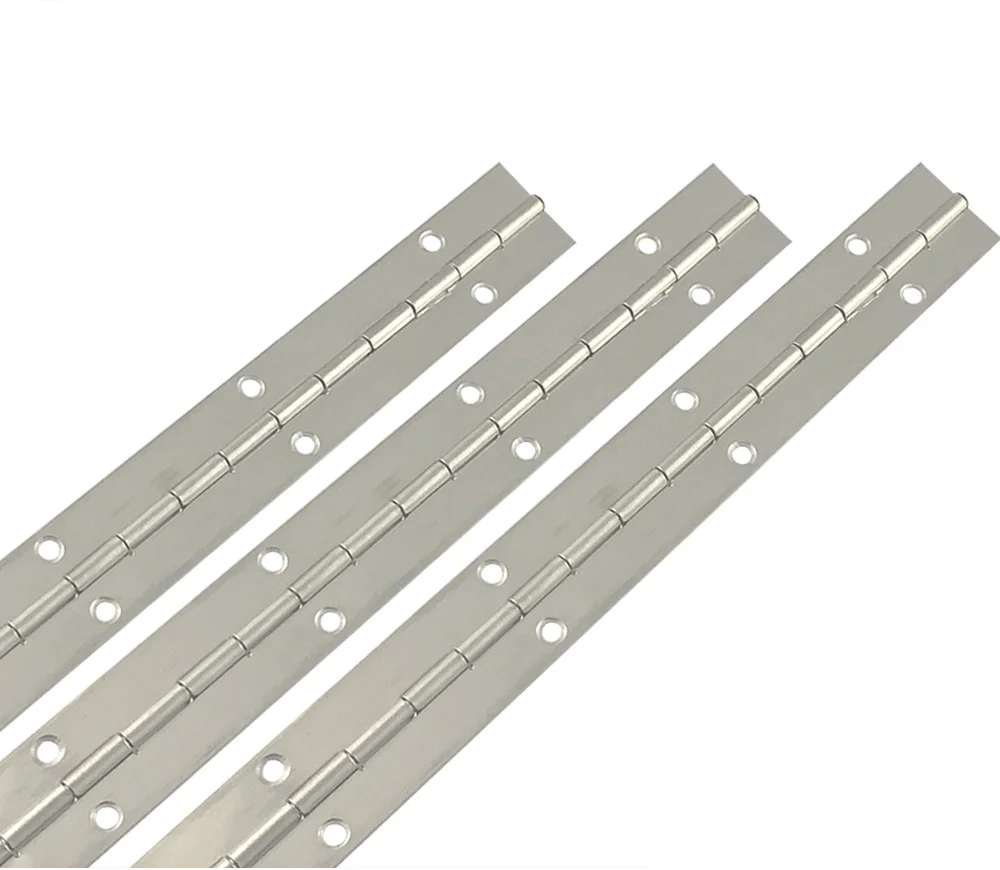

• Piano Hinges: Also known as continuous hinges, these run the entire length of the door and provide a strong, stable connection.

• Concealed Hinges: Often used in cabinetry, these hinges are hidden from view when the door is closed, offering a clean and sleek look.

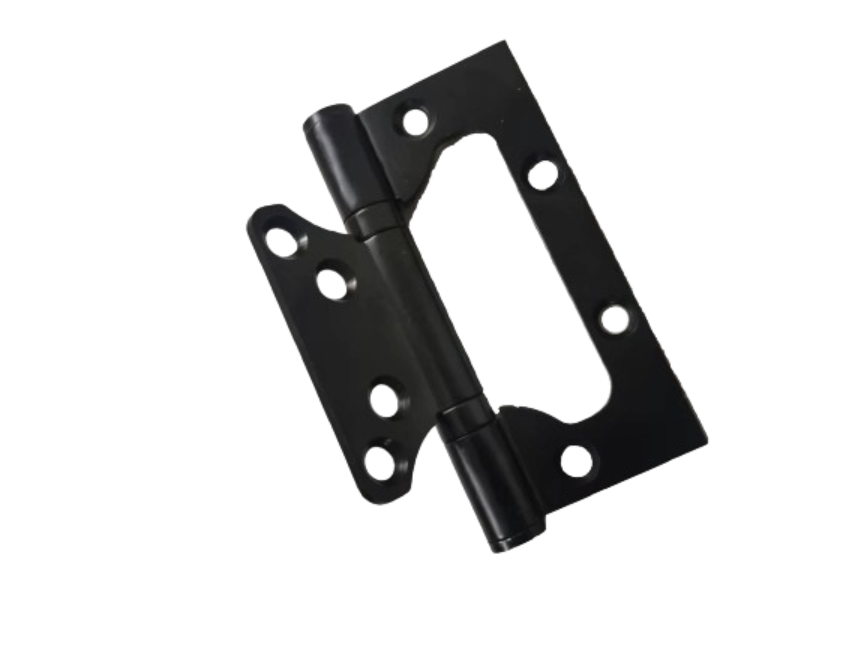

• Butterfly Hinges: Characterized by their decorative, butterfly-shaped leaves, these hinges are often used in furniture and cabinetry to add a touch of elegance.

Each type of hinge has its specific applications, and choosing the right one depends on the requirements of the project.

Focus on Butterfly Hinges

Butterfly hinges are renowned for their decorative appeal and functional versatility.

History of Butterfly Hinges

The use of butterfly hinges dates back several centuries. They became particularly popular during the 18th and 19th centuries, often seen in ornate furniture pieces.

The intricate designs of butterfly hinges made them a favored choice in period furniture, adding both functional support and decorative flair.

Over time, the design and materials of butterfly hinges have evolved, but their appeal remains strong in both antique and modern furniture designs.

Where Are Butterfly Hinges Used?

Butterfly hinges are are commonly used in a variety of applications where both functionality and aesthetic appeal are important. Here are some typical uses:

1. Furniture: Butterfly hinges are often found in furniture pieces such as cabinets, chests, and wardrobes. Their decorative appearance enhances the overall look of the furniture while providing the necessary support for opening and closing doors.

2. Cabinetry: In kitchen and bathroom cabinetry, butterfly hinges add a touch of elegance. They are ideal for vintage or rustic styles, contributing to the charm and character of the space.

3. Jewelry Boxes and Small Cases: Due to their small size and decorative nature, butterfly hinges are frequently used in jewelry boxes, keepsake boxes, and other small cases, providing a delicate yet functional hinge solution.

4. Interior Doors: While less common than in furniture, butterfly hinges can also be used on lightweight interior doors, particularly in homes with a traditional or antique aesthetic.

5. Decorative Projects: Crafters and DIY enthusiasts often use butterfly hinges in various decorative projects, such as creating custom picture frames, decorative shutters, or other artistic pieces that benefit from both functionality and decorative appeal.

Importance of Quality in Butterfly Hinges

For wholesalers and importers, the quality of butterfly hinges cannot be overstated. High-quality hinges lead to greater customer satisfaction, fewer returns, and a solid reputation in the market. Here’s why quality matters:

• Customer Satisfaction: Quality hinges ensure smooth operation and long-lasting performance, leading to happier customers.

• Reduced Returns: Investing in high-quality hinges minimizes the likelihood of product returns due to defects or failures.

• Market Reputation: Offering quality products helps build a strong reputation, attracting more business and repeat customers.

Key Materials for Butterfly Hinges

Butterfly hinges can be made from various materials, each offering different advantages and drawbacks:

• Stainless Steel: Known for its strength and corrosion resistance, stainless steel is ideal for both indoor and outdoor applications. also in stainless steel materials, there are sus304 and sus 201 for options.

• Brass: This material offers a classic look and excellent resistance to corrosion, making it suitable for decorative applications.

• Iron: Often used in rustic or antique furniture, iron hinges are strong but may require additional treatments to prevent rust.

• Zinc Alloy: Lightweight and corrosion-resistant, zinc alloy is a cost-effective option for decorative hinges.

Choosing the right material depends on the intended use, environmental conditions, and budget.

Durability Factors to Consider

Durability is a crucial aspect of butterfly hinges. Here are the key factors to consider:

• Corrosion Resistance: For outdoor or high-humidity environments, hinges must resist rust and corrosion. Stainless steel and brass are excellent choices for such conditions.

• Wear and Tear Resistance: The material and construction of the hinge affect its ability to withstand daily use. High-quality manufacturing processes and materials ensure better resistance to wear and tear.

• Load-Bearing Capacity: Ensure the hinge can support the weight of the door or panel it is attached to. This is particularly important for larger or heavier doors.

Installation and Usage Guide

How to install butterfly hinges?

Installing butterfly hinges correctly is essential for their optimal performance. Here’s a step-by-step guide:

Tools Needed:

• Screwdriver or drill

• Screws (usually provided with the hinges)

• Measuring tape • Pencil • Chisel (for mortise hinges)

Installation Steps:

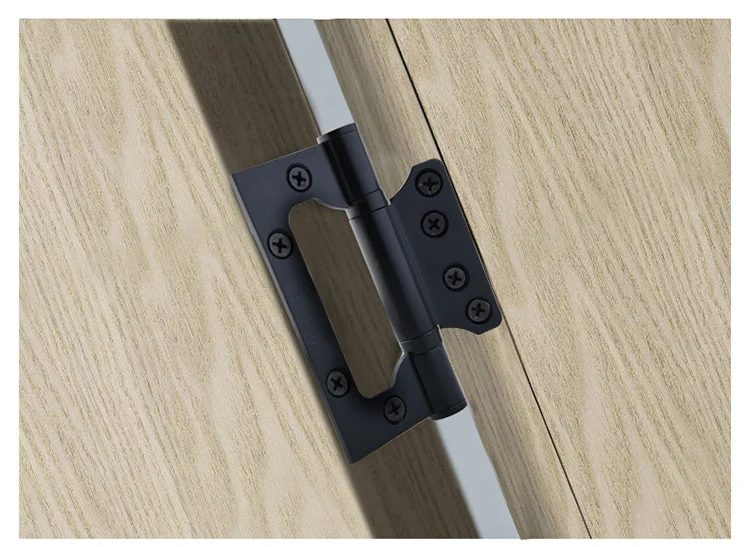

1. Positioning the Hinges: Mark the positions where the hinges will be installed on both the door and the frame. Typically, hinges are placed 5 inches from the top and bottom edges.

2. Mortising (if needed): If the hinges are mortise hinges, use a chisel to create shallow recesses where the hinge leaves will sit flush with the surface.

3. Attaching the Hinges: Align the hinges with the marked positions and use screws to secure them in place. Ensure the screws are tight and the hinge leaves are aligned correctly.

4. Testing the Door: Once the hinges are installed, test the door to ensure it opens and closes smoothly without any binding or resistance.

Quality Control and Certification

Ensuring the quality of butterfly hinges involves rigorous quality control measures. Here are key aspects wholesalers should consider:

• ISO Certification: Look for manufacturers with ISO certification, indicating adherence to international quality standards.

• Quality Testing Procedures: Manufacturers should conduct tests for load-bearing capacity, corrosion resistance, and wear and tear.

• ANSI/BHMA Standards: Ensure the hinges meet ANSI/BHMA standards for performance and durability.

Comparing Manufacturers and Suppliers

Choosing the right manufacturer or supplier is critical for ensuring consistent quality. Here’s how to evaluate potential partners:

• Product Quality: Request samples and inspect the quality of materials and construction.

• Production Capacity: Ensure the manufacturer can meet your order quantities and delivery timelines.

• Reputation: Research the manufacturer’s reputation in the industry through reviews and references.

• Factory Visits: Whenever possible, visit the manufacturing facility to see their processes and quality control measures firsthand.

Cost vs. Quality: Finding the Right Balance

Balancing cost and quality is crucial for wholesalers. Here are some strategies:

• Evaluate Long-Term Benefits: Investing in higher-quality hinges may have higher upfront costs but can lead to fewer returns and greater customer satisfaction.

• Negotiating with Suppliers: Establish strong relationships with suppliers to negotiate better prices without compromising on quality.

• Diversifying Suppliers: Source from multiple suppliers to avoid over-reliance on a single source and to ensure competitive pricing. at this points, manufacture always can not well-pleasing as supplier.

Case Studies and Examples

Case Study 1: A Wholesaler’s Success with High-Quality Butterfly Hinges

One of E-star customer in the U.S. switched to high-quality stainless steel butterfly hinges and saw a 30% increase in repeat business. Customers appreciated the durability and smooth operation, leading to positive reviews and increased sales.

Case Study 2: Issues with Low-Quality Hinges

Another E-star used customer from in Saudi faced significant returns and complaints in a period of time due to low-quality iron butterfly hinges that rusted quickly. After switching to stainless steel hinges, customer satisfaction improved, and returns decreased by 50%.

Conclusion

Focusing on the quality and durability of butterfly hinges is essential for wholesalers and importers. not only focused on price,by understanding the materials, installation techniques, and quality control measures, you can make informed decisions that enhance customer satisfaction and business success.

Investing in high-quality butterfly hinges not only reduces returns and complaints but also builds a strong market reputation.

If you’re looking for high-quality butterfly hinges that combine durability and aesthetic appeal, contact us today. E-Star offer a wide range of butterfly hinges in various materials and finishes to meet your specific needs. Get in touch for exclusive offers and to learn more about our products.