Introduction

Why Most Shower Door Seal Problems Are Size Problems

When a shower door leaks, most people immediately blame the seal material, the profile shape, or the installation method. In reality, incorrect size selection is the root cause of most failures.

PVC shower door seal strips are not universal components. They are engineered to work within very specific glass thickness ranges, and once the channel size is wrong, no profile design or installation technique can compensate for it.

This article focuses on one thing only: how to select the correct PVC shower door seal strip size based on glass thickness, specifically for 6mm, 8mm, 10mm, and 12mm glass.

It does not repeat basic explanations of what a seal strip is. Instead, it explains how size affects grip, sealing performance, durability, and safety, so readers can make correct decisions without trial and error.

Shower Glass Thickness: What the Numbers Really Mean

Shower glass thickness is always quoted as a nominal value — 6mm, 8mm, 10mm, or 12mm — but in practice, no tempered glass panel is perfectly uniform.

Why it happens?

• Tempered glass has manufacturing tolerances,For example “8mm glass” may measure anywhere between 7.6mm and 8.2mm, “10mm glass” often varies by ±0.4mm

• Edge polishing slightly reduces thickness

• Thickness can vary from top to bottom

A PVC seal strip must therefore:

• Fit securely at the thickest point

• Maintain grip at thinner sections

• Avoid overstressing the glass edge

This is why precise channel design is more important than tightness.

How PVC Shower Door Seal Strip Size Is Defined?

A PVC shower door seal strip size refers to the internal channel width that grips the glass, not the gap it seals against water.

This distinction is critical.

One rule to remember:

Channel size = glass thickness

Sealing lip = gap size

If you confuse these two, the seal will fail no matter how good the material is.

Glass Thickness, Gap Size, and Seal Design — How They Actually Interact

Glass thickness, gap size, and seal design are independent variables. Each controls a different function.

What glass thickness controls

Glass thickness controls:

• Channel width

• Grip force

• Installation difficulty

• Long-term holding strength

A seal sized for 8mm glass:

• Will be loose on 6mm glass

• Will not safely install on 10mm glass

It does not control water sealing.

What gap size controls

Gap size controls:

• Sealing lip length

• Number of lips

• Need for drip rail or deflector

Two doors using the same 8mm glass may need completely different seals if:

• One has a 6mm bottom gap

• The other has a 15mm bottom gap

This is why size selection must always start with glass thickness first, then lip design second.

PVC Shower Door Seal Strip for 6mm Glass

What is unique about 6mm glass?

6mm glass is lightweight and slightly flexible. This creates two challenges:

1. The glass provides less resistance for the seal to grip

2. Excessively hard PVC can cause slipping instead of holding

What a correct 6mm seal must do

A proper 6mm PVC seal must:

• Use a precisely sized but flexible channel

• Rely on material elasticity, not brute tightness

• Allow snap-on installation by hand

Soft to medium-soft PVC performs best here.

Common mistakes with 6mm PVC Shower Door Seal Strip

• Using seals designed for 8mm glass “because they feel tighter” • Choosing reinforced or rigid profiles meant for thicker glass

These mistakes cause:

• Gradual seal migration

• Poor long-term grip

• Increased leakage over time

Key decision rule:

For 6mm glass, flexibility and tolerance compensation matter more than stiffness.

PVC Shower Door Seal Strip for 8mm Glass

Why 8mm glass is the industry standard?

8mm glass offers the best balance between structural stability and door weight, it is highly compatible with hinges and seals. As a result, most PVC seal profiles are originally engineered around 8mm glass dimensions.

What a correct 8mm seal should feel like

A properly sized 8mm PVC seal should:

• Install with firm hand pressure

• Stay in position without adhesive

• Not require tools or force

If installation feels too easy, the channel is likely oversized.

If it requires force, the channel tolerance is wrong.

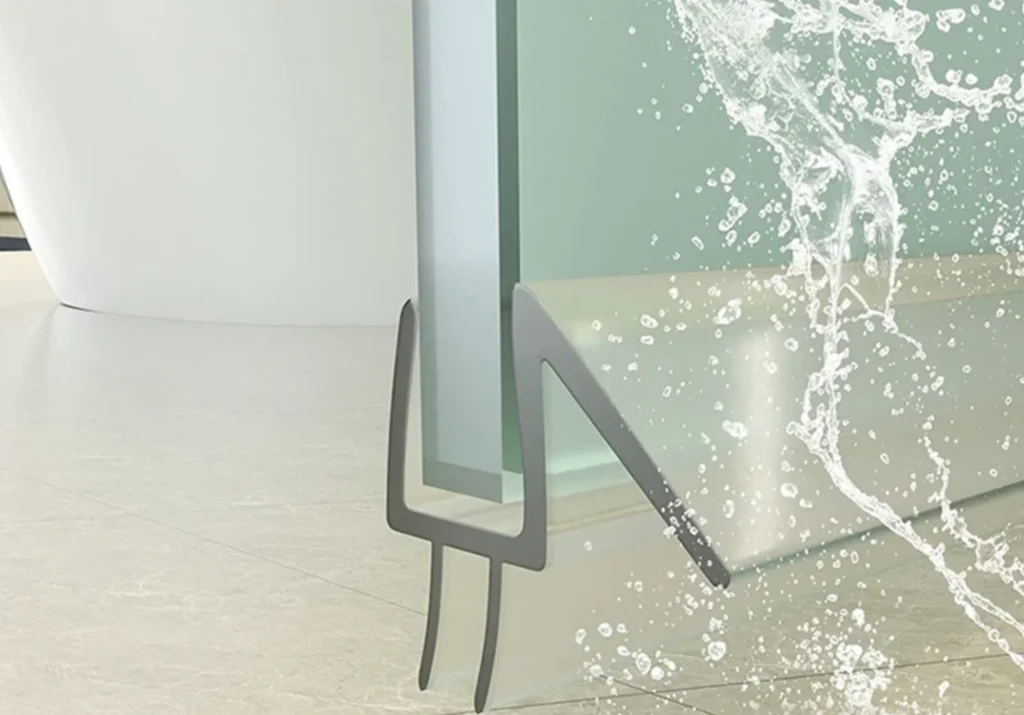

Bottom seal strip vs vertical shower door seal strip on 8mm glass

Although both use the same channel size, they serve different purposes:

• Bottom seal strip manages water volume and floor irregularities

• Vertical shower door seal strip prevents splash-through and air movement

Using the correct size but wrong application type is a common installation error.

PVC Shower Door Seal Strip for 10mm Glass

10mm glass introduces significantly more mass. This affects the seal in three ways:

• Increased downward load

• Higher friction during door swing

• Greater long-term stress on the channel

At this thickness, seal failure is usually caused by structural deformation, not poor sealing lips.

What a proper 10mm PVC glass door seal requires

A reliable 10mm glass door seal must have:

1. Rigid channel walls to resist spreading

2. Controlled hardness, not extreme softness

3. Flexible sealing lips that do not rely on channel compression

If sealing performance depends on forcing the channel tighter, the seal will fail.

Common 10mm sizing Shower Door Seal Strip mistake

Many buyers try to use “Very tight 8mm seals” or “Extra soft 10mm seals for easy installation”

Both approaches result in Channel distortion, Uneven grip and Seal slipping after months of use

so the correct logic is

At 10mm, strength must come from design, not tightness.

PVC Shower Door Seal Strip for 12mm Glass

12mm glass is typically used in Luxury bathrooms,Walk-in wet rooms or Architectural shower designs. Its weight and rigidity push standard PVC seals to their limits.

Why standard seals often fail on 12mm glass?

Common failure reasons:

• Channel walls spread under constant load

• PVC loses elastic recovery

• Sealing lips compress unevenly

These are design limitations, not material quality issues.

When custom PVC seals are the correct solution?

For 12mm glass, custom extrusion often provides:

• Tighter tolerance control

• Optimized hardness distribution

• Correct length without aggressive cutting

This is where OEM solutions outperform off-the-shelf products.

PVC Shower Door Seal Strip Size Charts (Practical Use)

Glass Thickness vs Channel Size

| Glass Thickness | Recommended Channel | Typical Use |

| 6mm | 6mm ±0.3mm | Sliding & framed doors |

| 8mm | 8mm ±0.3mm | Frameless showers |

| 10mm | 10mm ±0.3mm | Premium & hotels |

| 12mm | 12mm ±0.3mm | Luxury wet rooms |

Recommended PVC Hardness by Glass Thickness

| Glass Thickness | PVC Hardness | Reason |

| 6mm | Soft–Medium | Grip + flexibility |

| 8mm | Medium | Balance |

| 10mm | Medium–Hard | Structural stability |

| 12mm | Hard + soft lip | Load resistance |

How to Measure Shower Glass Correctly

Why single-point measurement fails

Glass thickness often varies slightly. Measuring only once can result in:

• Over-tight seals

• Installation difficulty

• Long-term glass stress

Correct measuring method

1. Measure at top, middle, and bottom 2. Use the maximum reading 3. Select the channel size accordingly

PVC flexibility absorbs smaller variations, but glass does not forgive undersizing.

Universal vs Size-Specific PVC Seal Strips

Universal seals rely on excessive deformation to fit multiple sizes. This leads to:

• Reduced grip strength

• Permanent deformation

• Shorter service life

Size-specific seals maintain:

• Consistent compression

• Stable grip

• Predictable performance

Standard Length vs Custom Length PVC Seal Strips

Common Market Lengths:

• 900mm

• 1000mm

• 2000mm

Custom Length Advantages

• Reduced waste • Cleaner installation • OEM branding options

Size Selection by Door Type

• Pivot doors: require strong bottom grip • Hinged doors: need balanced flexibility • Sliding doors: favor low-friction seals • Fixed panels: prioritize vertical stability

Door type determines how the seal is stressed, not the size itself.

Frequently Asked Questions

Can I use an 8mm seal on 10mm glass?

No. This can damage the glass and cause failure.

How tight should a PVC seal fit?

Firm hand pressure installation without tools.

Do thicker doors need harder PVC?

Yes, especially for 10mm and 12mm glass.

Conclusion:

Correct PVC shower door seal selection follows a clear order:

1. Measure glass thickness

2. Choose matching channel size

3. Select lip design based on gap

4. Adjust hardness for door weight

5. Use custom solutions when standard fails

If size is correct, sealing becomes predictable, durable, and safe.

Looking for the Right PVC Shower Door Seal Strip Size?

Choosing the correct PVC shower door seal strip size is critical for sealing performance, durability, and installation safety. If you are unsure which size, hardness, or profile best fits your application, professional guidance can save time and prevent costly mistakes.

We supply PVC shower door seal strips for 6mm, 8mm, 10mm, and 12mm glass, including:

• Bottom seals, vertical seals, and drip rail designs

• Standard and custom lengths

• Soft, medium, and hard PVC options

• OEM and private-label solutions

Contact us today to discuss your glass thickness, door type, and installation conditions.

Our technical team can recommend the most suitable seal or develop a custom PVC extrusion for your project.