Introduction

In modern architectural design, the shower enclosure has evolved from a purely functional area into an important aesthetic and comfort feature of the bathroom. One of the most critical components ensuring the long-term performance of a shower enclosure is the shower seal strip. While often overlooked, this small accessory determines whether the shower enclosure remains watertight, hygienic, and easy to maintain.

However, even the best-designed shower systems can experience performance issues over time, usually related to seal strip degradation. Factors such as water pressure, cleaning agents, temperature variation, and mechanical stress can cause the seal to deform, discolor, or detach.

This article provides a comprehensive technical discussion on the 8 most common problems with shower seal strips, including causes, consequences, and effective solutions. In addition, we introduce Dortec’s professional range of shower seal strips — model CB010, CB11, CB12, and CB13 — all designed for long service life, easy installation, and OEM customization options.

What Is a Shower Seal Strip?

A shower seal strip is a linear sealing component installed along the edges of glass shower doors and panels. Its primary function is to prevent water leakage from the shower enclosure while ensuring smooth door operation and soundproofing.

Typically made from PVC, silicone, or rubber, the seal strip fits between the glass and frame or along the glass edge itself in frameless systems. Depending on the door design, it can be positioned at the bottom, side, or magnetic closing edge.

Common Materials

• PVC (Polyvinyl Chloride): Durable, cost-effective, and commonly used for straight seals like E-Star CB010 and CB11 models.

• Silicone: Offers superior flexibility and temperature resistance but is softer and more expensive.

• Rubber or Co-extruded PVC: Provides enhanced sealing and anti-slip performance.

Common Types of Shower Seal Strips

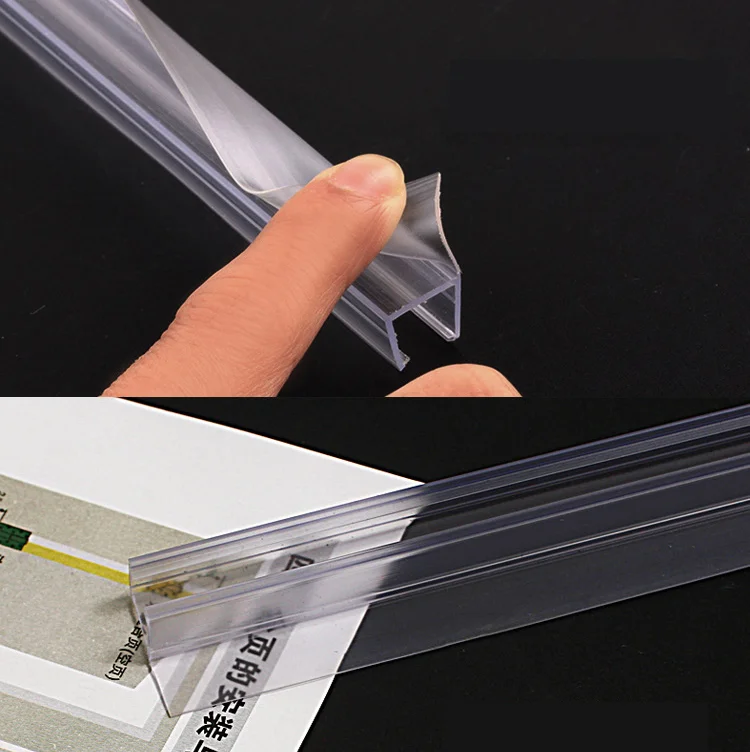

• H-Shape Seal (e.g., E-Star CB010): Ideal for connecting fixed glass and door panels.

• A-Shape Seal (e.g., E-Star CB11): Used for side sealing and tight door alignment.

• Brush Seal (e.g., E-Star CB12): Adds dust and noise protection.

• Magnetic Seal (e.g., E-Star CB13): Ensures automatic closure of frameless glass doors.

These variations allow for compatibility with different glass thicknesses (typically 6–12 mm) and structural layouts.

Why Shower Seal Strips Matter

A shower seal strip plays several critical roles in both function and safety:

• Waterproofing: Prevents leaks from the door gaps, protecting bathroom flooring and nearby walls.

• Hygiene: Stops the accumulation of mold and bacteria caused by standing water.

• Soundproofing: Reduces door noise during operation.

• Structural Protection: Prevents glass-to-glass or glass-to-metal contact that may cause chipping.

• Energy Efficiency: Keeps warm steam inside the enclosure for user comfort.

Without a reliable seal strip, even a premium shower door system can fail in a short time, leading to expensive maintenance and user complaints.

E-Star Hardware Supply reliable sealing solutions for both residential and commercial glass systems.

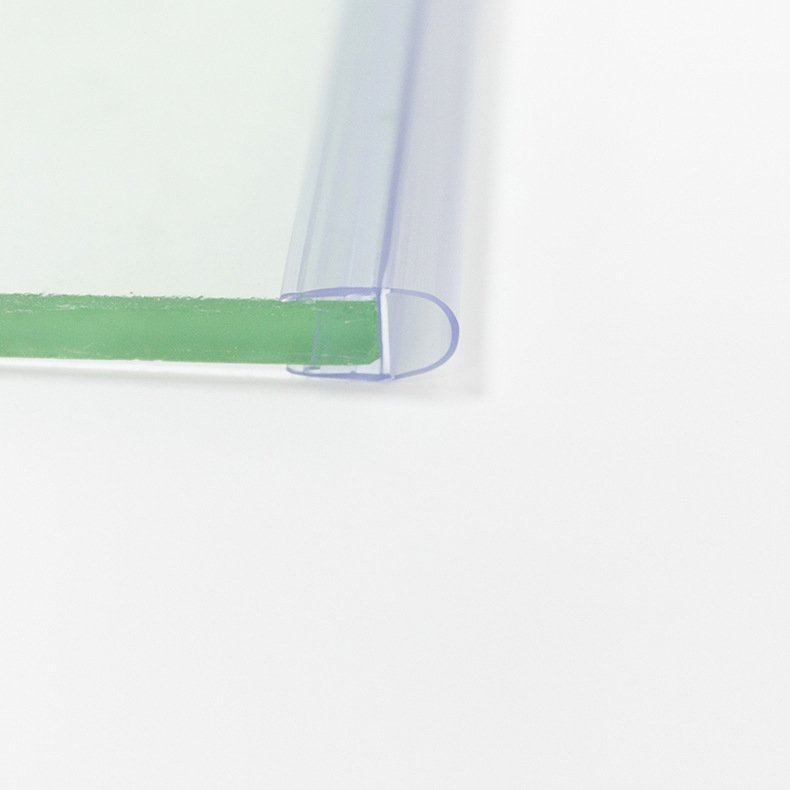

- CB010 – PVC H-Shape Seal Strip

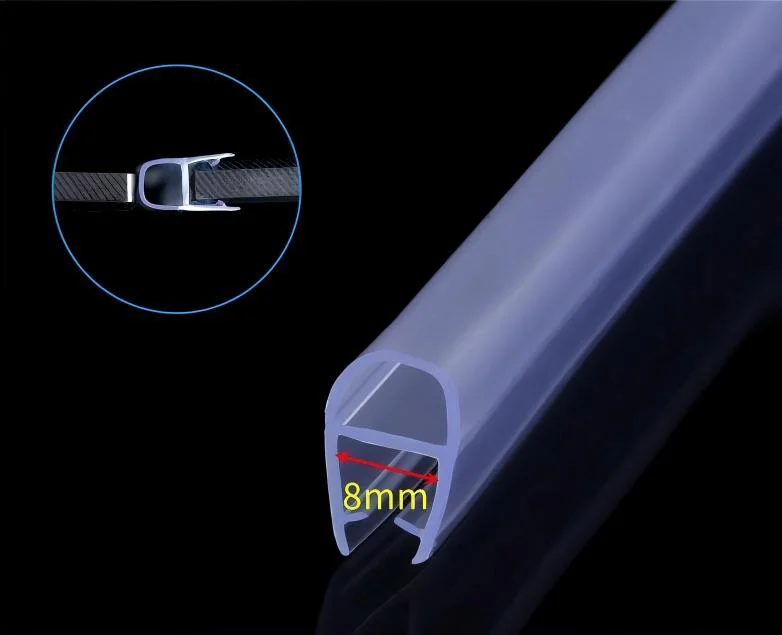

• Material: High-clarity PVC

• Recommended Glass: 8–10 mm

• Hardness: Shore A 70 ±5

• Length: Standard 2.0 m / Customizable

• Function: Connects fixed and moving glass panels, prevents side leaks

• Feature: Excellent resilience, easy installation

- CB11 – PVC A-Shape Seal Strip

• Material: Transparent PVC

• Recommended Glass: 8–10 mm

• Application: Side seal or gap closure between swinging door and wall glass

• Feature: Tapered design for tight sealing without affecting hinge movement

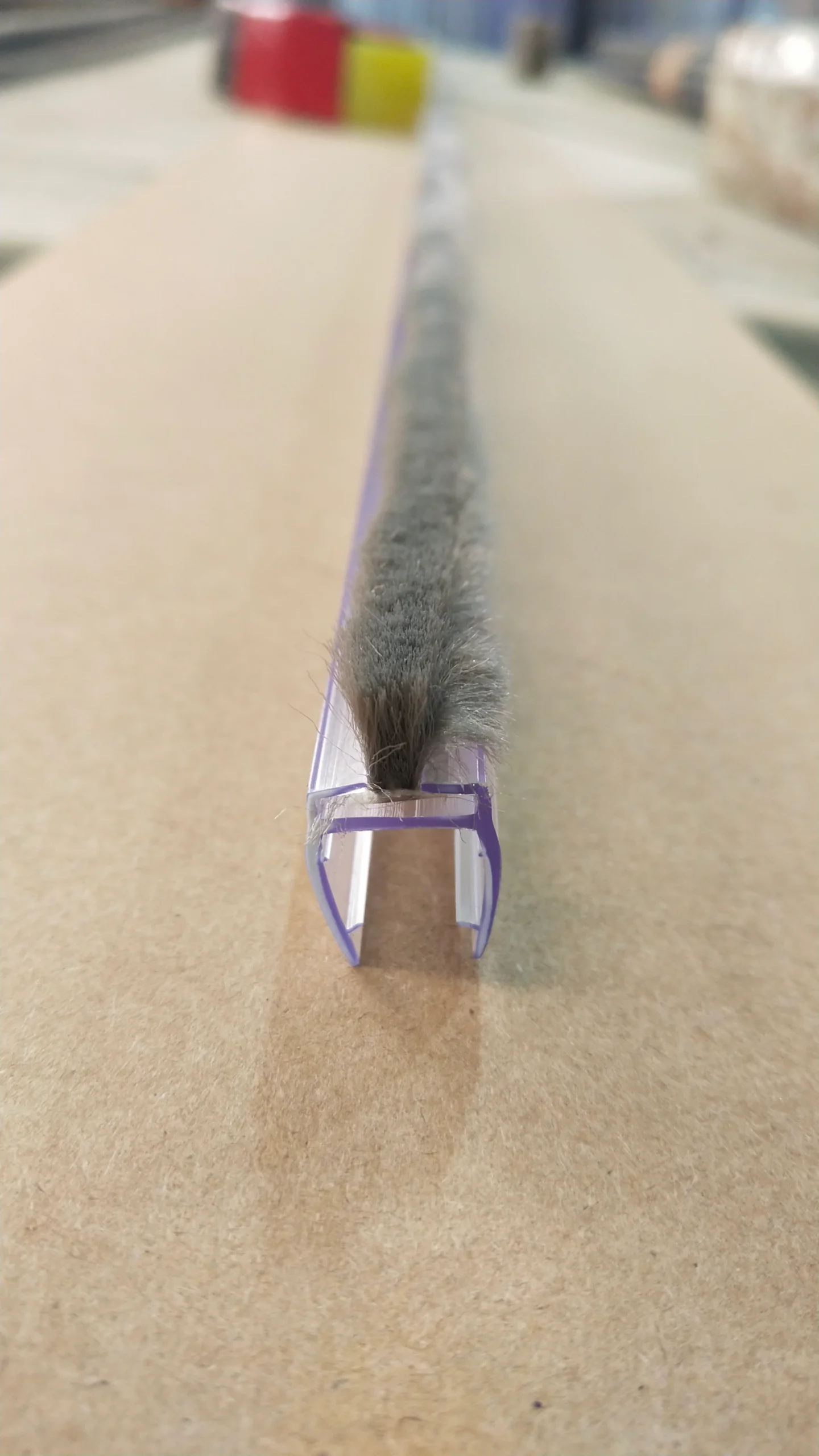

- CB12 – Seal Strip with Brush

• Material: PVC base with nylon brush

• Glass Compatibility: 8–10 mm

• Function: Blocks dust, reduces noise, and increases ventilation

• Feature: Replaceable brush insert, ideal for sliding shower doors

4. CB13 – Magnetic Seal Strip

• Material: PVC with embedded neodymium magnets (N38 grade)

• Glass Compatibility: 8–10 mm

• Function: Automatic magnetic closing and noise insulation

• Feature: Combined sealing and brush performance for premium enclosures

8 Common Problems with Shower Seal Strips

Problem 1: Water Leakage Around the Door

Cause:

• Worn-out seal edges

• Improper seal type or incorrect size

• Poor alignment during installation

Solution:

Inspect the gap between the door and fixed panel. If the seal has become rigid or cracked, replace it with a suitable new strip. For most side or bottom leaks, E-Star CB010 (H-shape PVC seal) provides an efficient barrier for 8–12 mm glass. Its precise extrusion and flexible fins ensure tight sealing and long service life.

Problem 2: Seal Strip Turning Yellow or Discolored

Cause:

• Prolonged UV exposure and detergent chemical reaction

• Low-grade PVC or silicone material

Solution:

Use high-quality, UV-stabilized PVC material such as that used in E-Star CB11 (A-shape PVC seal). Regular cleaning with mild soap and avoiding chlorine-based cleaners can also slow discoloration.

Problem 3: Mold or Mildew Buildup

Cause:

• Water trapped in seal gaps

• Lack of ventilation or poor drainage design

Solution:

Remove and clean the seal periodically. Replace old seals with E-Star CB12, which integrates a brush insert to enhance air circulation and minimize moisture accumulation. For industrial projects, request Dortec’s anti-fungal PVC material for extended hygiene performance.

Problem 4: Seal Hardening or Cracking Over Time

Cause:

• Exposure to hot water and bathroom temperature changes

• Low-quality or aged material losing plasticity

Solution:

Replace with a high-flexibility PVC or co-extruded strip. Dortec’s seal strips are formulated with an optimal Shore A hardness of 70 ±5, offering a balance between rigidity and resilience. For applications exposed to high temperatures, Dortec recommends a silicone-based variant customized through OEM orders.

Problem 5: Seal Coming Loose or Falling Off

Cause:

• Incorrect size (too loose)

• Repeated door movement

• Adhesive failure (for stick-on types)

Solution:

Check glass thickness and match the proper groove dimension. E-Star CB010 and CB11 are manufactured in multiple internal widths to fit 6, 8, 10, or 12 mm glass panels. Their extrusion precision tolerance is within ±0.1 mm, ensuring a secure press-fit without adhesives.

Problem 6: Door Not Closing Properly

Cause:

• Seal deformation interfering with hinge movement

• Misaligned magnetic seals or incorrect thickness

Solution:

Choose a magnetic seal such as that provides balanced magnetic force while maintaining flexibility. Ensure the seal profile matches the hinge geometry to avoid friction. For pivot-type doors, the A-shape is more suitable for side sealing without interfering with the swing radius.

Problem 7: Noise When Opening or Closing Door

Cause:

• Hard or dry contact between the seal and glass

• Inappropriate seal hardness

Solution:

Apply a soft PVC or silicone seal strip. undergo anti-friction surface treatment during extrusion to minimize squeaking. The CB12 brush seal is particularly effective for reducing operational noise in frameless shower door.

Problem 8: Gaps Between Glass and Seal Strip

Cause:

• Improper sizing or glass tolerance variation

• Shrinkage of old PVC due to age

Solution:

Replace the seal with a properly dimensioned model. E-Star offers OEM customization of seal dimensions and length, allowing manufacturers and installers to match non-standard glass tolerances. CB010 and CB11 can be produced in lengths up to 2.5 meters or custom cut to order.

How to Fix or Replace a Shower Seal Strip

Replacing a shower seal strip is straight forward but requires precision to maintain watertight integrity.

Step 1: Remove the Old Seal

Pull off the existing strip gently. For adhesive types, use a scraper and mild detergent to clean the surface.

Step 2: Measure the Glass Thickness and Gap

Use calipers to confirm glass thickness. Choose the corresponding seal groove size (6 mm, 8 mm, 10 mm, or 12 mm).

Step 3: Cut the New Seal to Length

Dortec’s seal strips are supplied in 2.0 m or 2.5 m standard lengths, but can be OEM customized upon request. Cut the strip to match your door edge precisely.

Step 4: Install the New Seal

Align and push the strip firmly along the glass edge. For magnetic types (CB13), ensure polarity alignment.

Step 5: Check Functionality

Close the door to verify sealing and motion smoothness. Adjust if necessary.

How to Choose the Right Shower Seal Strip

Selecting the correct seal depends on several technical factors:

| Parameter | Recommended Specification | Example E-Star Model |

| Glass Thickness | 6–12 mm | CB010 / CB11 |

| Seal Type | H-shape, A-shape, Brush, Magnetic | CB010, CB11, CB12, CB13 |

| Material | PVC (standard), Silicone (custom) | CB010–CB13 |

| Shore A Hardness | 70 ±5 | All models |

| Operating Temperature | -20°C to +70°C | All PVC models |

| OEM Custom Length | Up to 3m | All models |

| Special Features | Brush insert, Magnetic closure | CB12, CB13 |

By evaluating these parameters, specifiers and OEM clients can ensure the correct seal is chosen for each application.

E-Star understands that every project has unique dimensional and performance requirements. To meet this demand, the company offers:

• OEM and ODM manufacturing

• Custom length extrusion (up to 2.5 meters or as per client drawing)

• Special hardness formulation (from Shore A 60 to 80)

• Packaging customization for export markets

All E-Star products are produced under strict quality control and ISO-compliant manufacturing standards, ensuring high consistency across every batch.

How Long Do Shower Seal Strips Last?

The service life of a shower seal strip depends on:

• Material type (PVC: 3–5 years; Silicone: 5–8 years)

• Installation environment (humidity, temperature)

• Maintenance frequency

To extend lifespan:

• Clean the seal weekly with neutral detergent.

• Avoid harsh chemicals and direct sunlight exposure.

• Replace seals showing visible cracks or deformation.

E-Star premium PVC compounds are engineered for long-term flexibility and color stability, offering up to 50,000 open/close cycles under laboratory testing conditions.

Conclusion

While shower seal strips may appear to be minor accessories, they play a decisive role in ensuring the functionality, safety, and aesthetics of a shower enclosure. Most common problems—such as leakage, discoloration, or deformation—can be easily prevented or corrected by selecting the right product and maintaining it properly.

E-Star’s CB010, CB11, CB12, and CB13 series provide comprehensive solutions for various shower door systems. With precision extrusion, durable materials, and OEM customization capability, Dortec is your reliable partner for high-performance shower sealing components.

For bulk orders, OEM projects, or technical consultation, please contact E-Star sales team to discuss customized sealing solutions that match your project requirements.