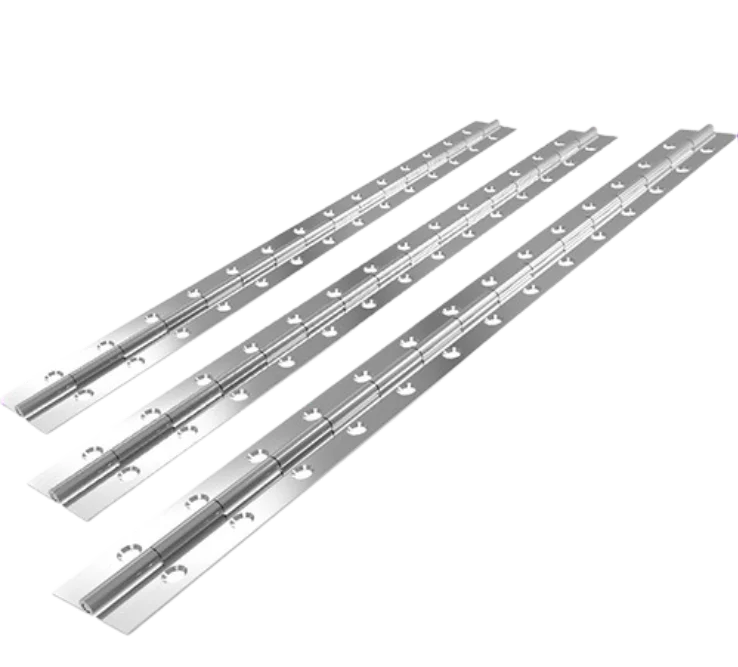

Continuous hinges, commonly known as piano hinges, are essential components in doors, cabinets, and industrial applications where durability and smooth operation are required. Unlike traditional hinges that have multiple separate pivot points, continuous hinges run along the entire length of the door or panel, distributing weight more evenly.

However, not all continuous hinges offer the same weight-bearing capacity. Several factors determine how much load a hinge can support, affecting its durability and long-term performance. In this blog, we will explore the key factors that influence the weight-bearing capacity of continuous hinges, helping you make an informed decision when selecting the right hinge for your application.

Table of Contents

Are continuous hinges strong?

Continuous hinges are generally strong due to the factors as follows:

Even Load Distribution

Continuous door hinges run the entire length of the door, panel, or box, providing maximum, uniform support. This even distribution of the load reduces stress concentration points, enabling the hinge to bear more weight without being easily deformed or damaged.

Solid Structure

Usually, continuous hinges are made of a single long piece of material, which has better structural integrity compared to some segmented hinges. The connection between the two leaves of the hinge and the pin is also relatively stable, which can withstand greater force during the opening and closing process of the door.

High-Quality Materials

Continuous hinges are often made of materials such as steel, stainless steel, aluminum, and brass, which have high strength, stiffness, and corrosion resistance. These materials can ensure the durability and strength of the hinges, enabling them to maintain good performance under harsh conditions.

Excellent Manufacturing Process

In the manufacturing process of continuous hinges, advanced technologies and processes are usually employed to ensure the accuracy and surface quality of the hinges. For example, heat treatment can enhance the mechanical properties of the material, and surface treatment can improve the corrosion resistance of the hinge. Moreover, reliable connection methods such as welding and riveting are used to ensure the stability of the hinge.

How much weight can continuous hinges support?

The weight that continuous hinges can support varies depending on factors like material, thickness, length, and pin diameter. Generally:

Standard Continuous Hinges

Steel: A standard steel continuous hinge, such as a 16-gauge steel piano hinge, can typically support 200 to 400 lbs (about 90 to 180 kg). These are often used in general-purpose applications like cabinets and light industrial doors.

Aluminum: Aluminum continuous hinges are usually lighter and have a load capacity of 100 to 300 lbs (about 45 to 135 kg). They are suitable for applications where weight is a concern and the load is relatively light, such as in some lightweight industrial settings or furniture.

Heavy-Duty Continuous Hinges

Stainless Steel: Heavy-duty stainless steel continuous hinges are capable of supporting 600 to 1,000 lbs (about 270 to 450 kg) or more. In industrial applications, there are even specialized versions that can exceed 1,000 lbs4. They are commonly used in industrial doors, large equipment enclosures, and high-security doors.

Other Materials: Some high-strength alloy or specialized material heavy-duty continuous hinges can also support weights in the range of 200 to 600 lbs (about 90 to 270 kg).

| Standard Continuous Hinges | Heavy-Duty Continuous Hinges | ||

| Steel | 200 to 400 lbs (about 90 to 180 kg) | Stainless Steel | 600 to 1,000 lbs (about 270 to 450 kg) or more |

| Aluminum | 100 to 300 lbs (about 45 to 135 kg) | Other Materials | 200 to 600 lbs (about 90 to 270 kg) |

Are there any factors that can affect the weight-bearing capacity of continuous hinges?

Yes, there are several factors that can affect the weight-bearing capacity of continuous hinges. The main aspects are as follows:

Hinge-related Factors

Material: Different materials have different mechanical properties. Steel has high strength and rigidity, enabling it to bear heavy weights. Stainless steel not only has high strength but also good corrosion resistance, which is suitable for harsh environments and can maintain its weight-bearing capacity. Aluminum is lightweight but has relatively lower strength than steel, so its weight-bearing capacity is limited. High-strength alloys have excellent comprehensive performance and can usually bear greater weights.

Thickness and Width: Thicker and wider continuous hinges generally have a greater weight-bearing capacity. A thicker hinge can provide more material support and can withstand greater stress. A wider hinge can increase the contact area with the door and the frame, evenly distributing the weight of the door and reducing the pressure per unit area, thereby improving the weight-bearing capacity.

Pin Diameter and Quality: The pin is a key part that affects the rotation and stability of the hinge. A larger diameter pin can withstand greater torque and shear force, improving the overall strength and weight-bearing capacity of the hinge. In addition, the quality of the pin, such as its material and manufacturing process, also has an impact. A high-quality pin with good wear resistance and strength can ensure the normal operation of the hinge under heavy loads.

Manufacturing Process: Advanced manufacturing processes can improve the quality and performance of hinges. For example, precision casting and forging processes can make the material structure of the hinge more compact and uniform, enhancing its strength and durability. Good surface treatment, such as electroplating and powder coating, can not only prevent corrosion but also improve the appearance quality of the hinge, which is also beneficial to its long-term use under load.

Continuous Door Hinge Installation and Use Environment Factors

Installation Method: The correct installation method is crucial for the weight-bearing capacity of the hinge. If the hinge is not installed firmly or is not installed in the correct position, it may cause uneven force on the hinge, reducing its weight-bearing capacity. For example, if the screws are not tightened or the installation holes are not drilled accurately, it will affect the connection between the hinge and the door and the frame, resulting in potential safety hazards under heavy loads.

Door Type and Structure: The type and structure of the door also have an impact on the weight-bearing capacity of the hinge. A solid wood door is usually heavier than a hollow door, so it requires a hinge with a greater weight-bearing capacity. In addition, the shape and size of the door, as well as whether there are additional accessories or decorations on the door, will all affect the distribution of the door’s weight and the force on the hinge.

Use Environment: The use environment has an important influence on the performance of the hinge. In a high-humidity or corrosive environment, the material of the hinge is prone to rust and corrosion, which will reduce its strength and weight-bearing capacity. In an environment with large temperature differences, the material of the hinge may expand and contract, affecting its fit and stability. In addition, frequent use and opening and closing of the door will also cause wear and tear on the hinge, gradually reducing its weight-bearing capacity over time.

How to choose the appropriate continuous door hinge according to the required weight-bearing capacity?

When choosing an appropriate continuous hinge based on the required weight-bearing capacity, the following steps and considerations are involved:

Determine the Weight of the Door or Object

Accurate Measurement: Weigh the door or the object that the hinge needs to support. For doors, consider not only the weight of the door leaf itself but also any additional components such as glass panels, hardware, or decorative elements. If it’s a custom-made door, obtain the weight specifications from the manufacturer. For other objects, use a suitable weighing scale to get an accurate weight value.

Estimate Dynamic Load: In addition to the static weight, consider the dynamic load that the hinge will experience. This includes forces generated during opening and closing, such as when the door is swung quickly or when there is wind pressure. A general rule of thumb is to add an extra 20% – 30% to the static weight to account for dynamic forces. For example, if a door weighs 100 kg, you should look for a hinge that can support at least 120 – 130 kg.

Consider Hinge Material and Characteristics

Material Selection:

- Steel: Ideal for heavy-duty applications where high strength and durability are required. It can withstand significant weights and is suitable for industrial doors, large cabinet doors, or doors in high-traffic areas.

- Stainless Steel: Offers excellent corrosion resistance, making it suitable for outdoor applications or environments with high humidity, such as bathrooms or kitchens. It also has good strength and can support moderate to heavy weights.

- Aluminum: Lighter in weight but still provides sufficient strength for lighter doors or applications where weight is a concern, like in some furniture or lightweight partition doors.

Hinge Design:

- Full Mortise vs. Half Mortise: Full mortise hinges are more concealed and provide a neater appearance, while half mortise hinges are easier to install and offer good support. For heavy doors, full mortise hinges are often preferred as they distribute the load more evenly.

- Piano Hinge vs. Other Types: Piano hinges, which are a type of continuous hinge, are known for their long, continuous design that provides uniform support along the length of the door. They are suitable for a wide range of applications and can handle different weights depending on their material and dimensions.

Check Hinge Specifications

- Load Capacity Ratings: Manufacturers usually provide load capacity ratings for their hinges. These ratings indicate the maximum weight that the hinge can support under normal conditions. Make sure to choose a hinge with a load capacity that exceeds the calculated weight of your door or object. For example, if your door weighs 150 kg, select a hinge with a load capacity of at least 180 kg to ensure safety and durability.

- Dimensions and Thickness: The length, width, and thickness of the hinge are important factors. A longer hinge can distribute the weight over a larger area, reducing stress on each point. A wider and thicker hinge will generally have a higher load-bearing capacity. For very heavy doors, you may need to choose a hinge with a larger cross-sectional area and a thicker material gauge.

Seek Professional Advice and References

- Consult Experts: If you’re unsure about the selection, consult a hardware specialist, architect, or door installer. They have practical experience and can provide valuable advice based on your specific application and requirements.

- Product Reviews and Case Studies: Look for product reviews and case studies online or in trade publications. This can give you an idea of how well a particular hinge performs in real-world applications and whether it has been successful in supporting similar weights

Frequently Asked Questions

Q:How to install a continuous hinge?

- Measure the door frame height and cut the hinge to the appropriate length, filing the edges.

- Remove and re – insert the hinge tip to secure the hinge pin.

- Position the hinge on the frame with proper gaps and screw it in place.

- Place the door in the opening, align it with the hinge, and screw the hinge to the door.

- If there’s a cover, attach it using the provided cover clips.

Q: How do I measure the correct length of the continuous hinge?

A: Measure the height of the door frame from the finished floor to the bottom of the frame header, then subtract 7/8 inches.

Q:Can a continuous hinge be used for heavy doors?

A:Yes, continuous hinges can be used for heavy doors, provided they are properly sized, material-grade matched, and installed correctly.

Conclusion

Choosing the right continuous hinge is essential for ensuring long-term durability and proper function. By considering material, hinge thickness, pin size, installation method, and environmental factors, you can select a hinge that meets your weight-bearing requirements.

At E-Star Hardware, we offer a wide range of high-quality continuous hinges designed for durability and heavy-duty applications. Contact us today to find the perfect hinge solution for your needs!